Control and information system

Quantity:

Features

Machine control

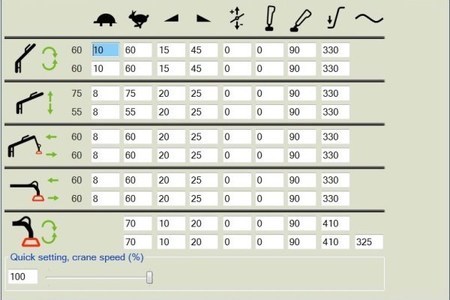

MaxiXT’s machine control is a market leader thanks to its full integration with other systems. Everything from engine and crane control and cab levelling to the transmission and ladders are encompassed. An unlimited number of users are easily created, as are a number of different operator profiles for working in different conditions. All operator-specific functions can be fine-tuned to achieve the exact sensitivity and speed – or smoothness and accuracy – that each operator prefers.

Head control

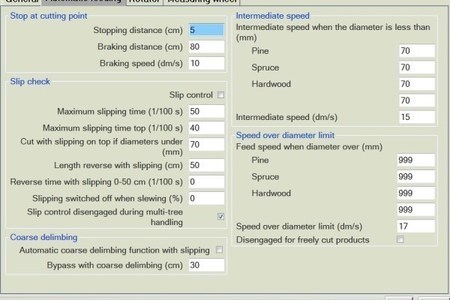

MaxiXT’s head control is one of the most multifaceted on the market. Together with the effective hydraulic system, it enables even the narrowest of cutting windows to be executed quickly and accurately. The power of the knives, feed rollers and tilt down function are easily adjusted using a graph and are determined by stem diameter and tree species. This offers optimal productivity, measurement accuracy and time savings. Other popular functions are bar rescue and clearing.

Area management

The operator creates areas with which information is associated during harvesting. An unlimited number of areas can be created. Sub-areas can be created under each area. Creating, switching and closing areas is easy as everything is managed in the same place, the Area Overview. MaxiXT can be configured so that all reporting is fully automated, without any interaction on the part of the operator.

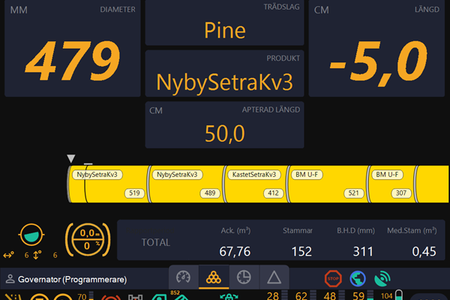

Bucking

MaxiXT can handle all bucking requirements, from simplest to full value-optimised bucking. Creating bucking instructions to optimize lengths is easy, using a method where the system selects the assortment and length based on a list of priorities. MaxiXT with value-optimised bucking offers some of the market's most efficient bucking, optimising value extraction based on sawmill preferences. Based on the documented exceptional measurement accuracy of Komatsu heads, volumes are calculated with great precision.

Equipment

PC designed especially for demanding forest machine environments. The hard drive is an SSD, which means fast read and write times, and the lack of moving parts means greater reliability and durability. USB port for quick and easy data transfers to and from USB flash drives. Transfer compatibility with GSM modem, GPRS, EDGE, CDMA450, WLAN, satellite and more. The optional 12-inch touchscreen can register clicks, gestures and swipes in the same way as a tablet PC or smartphone.

Service

MaxiXT displays alarms in working mode, indicating the cause and error code if anything goes wrong. Following acknowledgement, the alarm is saved in an exportable log file. All confirmed alarms are collected in a clear alarm list. Komatsu’s unique spare parts system, ESS, includes all machine components, article numbers, exploded views and more. The user-friendly troubleshooting tool enables extensive troubleshooting of the system’s hardware and network.

Decision support

MaxiXT also includes a number of advanced decision support systems and aids, such as for optimising off-road driving, measurement quality and simplifying communication with the outside world. Examples are MaxiS for stem profile and stem data, MaxiVision for maps and GIS information, ESS for spare parts and E-mail for Communication.